03/20/2018 / By Edsel Cook

A new pre-treatment process developed by Maryland engineers can produce extremely dense wood with more than 10 times the strength, toughness, ballistic resistance, and dimensional stability of normal wood. The developers claim the specific strength of their processed wood variant exceeds that of most structural metals and titanium alloys while being cheaper than carbon fiber.

The study was facilitated by University of Maryland, College Park and published in the journal Nature.

- Synthetic structural materials suffer disadvantages that offset their excellent strength and toughness. Traditional steels and alloys are heavy and produced through highly-polluting processes, while composites derived from polymers or bio-mimetics are prohibitively costly due to their elaborate manufacturing requirements.

- Cheap and commonplace, natural wood served for thousands of years as a structural material for construction. However, its mechanical strength is insufficient for major applications and engineering structures.

- Natural wood can be strengthened through pre-treatment processes combined with impregnation. However, current methods cannot achieve full densification. Current types of pre-treated wood are also unable to maintain their dimensions when exposed to humidity. Wood expands after absorbing water, which weakens its structural integrity.

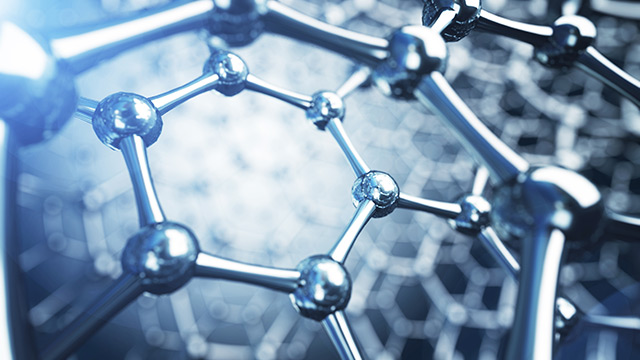

- Researchers devised a new two-step process to pre-treat wood. The first step boils natural wood in an aqueous mixture of sodium hydroxide (NaOH) and sodium sulphite (Na2SO3), which removes lignin and hemicellulose from the material. The second step is hot-pressing, which collapses cell walls and leads to full densification. Examination of cellulose nanofibers note their close alignment.

- The resulting wood was light, strong, and inexpensive. The pre-treatment process was demonstrated to be compatible with various types of lumber from different tree species.

The researchers believe their pre-treated wood can serve as an inexpensive and nature-friendly replacement for composites and metal alloys in building construction, car manufacturing, and others.

Journal reference

Song J, Chen C, Zhu S, Zhu M, Dai J, Ray U, Li Y, Kuang Y, Li Y, Quispe N, et al. PROCESSING BULK NATURAL WOOD INTO A HIGH-PERFORMANCE STRUCTURAL MATERIAL. Nature, vol. 554, no. 7691, 7 Feb. 2018, pp. 224–228., DOI: 10.1038/nature25476.